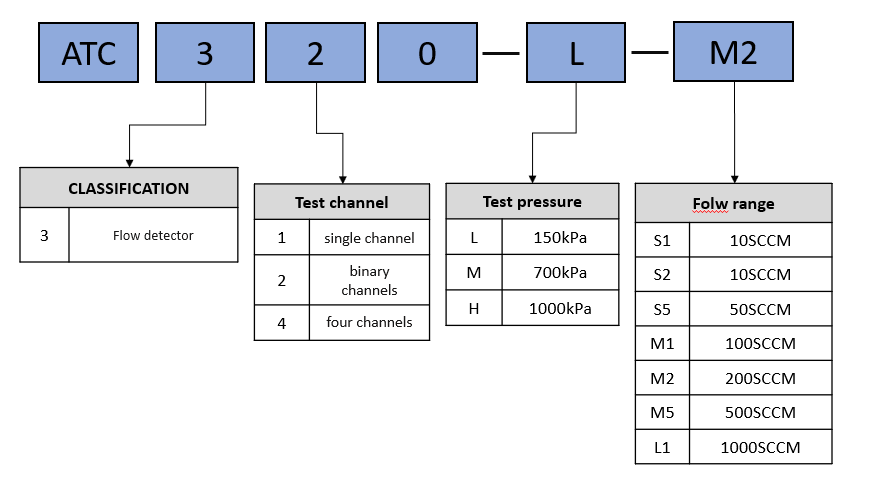

Flow tester

The ATC300 series flow type leak detector adopts a high-sensitivity inlet flow sensor with higher test accuracy; the economical and compact housing shape provides an ideal and effective technical solution for various assembly applications. The test result has nothing to do with the volume size and shape of the workpiece to be tested. It directly detects the actual air flow flowing through the tested channel, and the test result is directly displayed in the form of leak rate.

ATC300 flow type leak detector integrates high-resolution analog-to-digital conversion technology, signal processing, automatic setting, rapid inflation and testing capabilities, easy-to-operate interface and communication technology.

ATC300 flow type leak detector is a high-precision instrument that specializes in measuring the consistency of carburetor orifices, nozzles, gas nozzles and various apertures. This product has the characteristics of fast testing speed and high precision. It is especially suitable for small leakage detection of various solenoid valve cylinders, electronic components and gas appliance components. At the same time, this product is also a product that has a large leakage amount and can adjust the size of various valve openings.